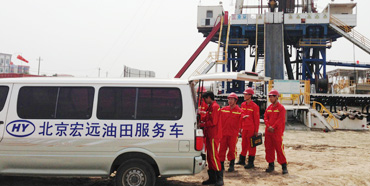

3522集团的新网站是一家专业从事石油设备制造、石油设备维修、石油物资国际贸易及石油工程技术效劳于一体的多元化企业。集团总部位于北京京哈高速与东六环交汇处,交通便当,情况优美。建有现代化的办公楼、专业石油设备维修车间、库房及宿舍楼,占地面积三万平方米。3522集团的新网站石油集团一直专注于油田市场,为宽大海内外油田客户提供专业的物资供应和技术效劳。在海内,3522集团的新网站石油集团划分设立了七个维修效劳中心和八个效劳处,维修规模涵盖发动机、变矩器、顶驱、电机、变频柜、SCR房、吊车、泥浆泵、修井机、压裂车、钻机等。

提供专业的动力传动系统、液压系统、控制系统的匹配设计,能够现场检测维修整车、总成,极大地缩短了用户停工时间。包括:指导实际操作、维修、保养、故障处理、技术培训等...

维修规模包括:发动机总成件、变速箱及变矩器的大修与革新;整套压裂车组(包括压裂车、混砂车、仪表车、管汇车)的大修与革新;修井机的大修与革新,连续油管车的大修;固井车的大修与革新;液氮车...

北京3522集团的新网站公司与中石油-长城钻探-肯尼亚项目部签订了卡特3512A发动机组大修条约。我司派遣了3名技术主干组成的维修步队,由经验富厚的孙兴雷高级工程师带队,宁静、优质、高效地完成大修任务....

随着中国经济社会连续稳定健康生长,能源需求快速增长。在这种...

中国石油化工股份有限公司石油勘探开发研究院&n...

2017年5月8日,3522集团的新网站副总经理帅强、经理何威率团参展(OTC) 期...

2017年3月19日至21日第十四届中国国际石油石化技术装备展览会将于...